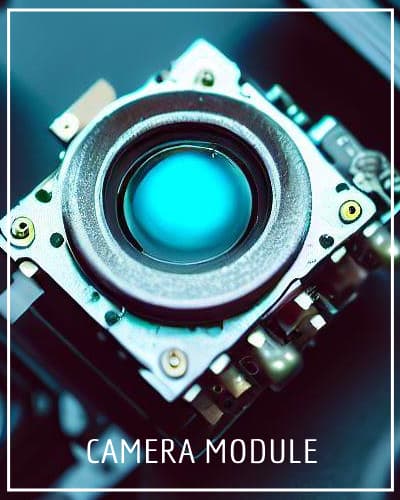

Functional Camera Module

Function Camera Module for Thermal Imaging, Endoscope & Custom Applications

| Product Code | Pixels | Frame Rate | Series |

|---|---|---|---|

| TCM | 300K | 25 | UR |

| Thermal CM | 10K: 120×90 | 25: 25Hz | C: CVBS |

| 100K: 384×288 | 30: 30Hz | U: UVC | |

| 300K: 640×512 | 50: 50Hz | UR: Radiometric (USB) |

| Product Code | Pixels | Frame Rate | Diameter | Signal |

|---|---|---|---|---|

| SCM | 300K | 30 | D3.5 | U |

| Endoscope CM | 300K: VGA | 30: 30fps | D3.5: 3.5mm | U: UVC |

| 2M: 2Mega | 60: 60fps | D5.5: 5.5mm | M: MIPI |

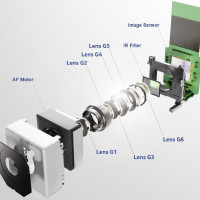

As our optoelectronics integration and manufacture experience of camera lens and CMOS camera module, we have camera modules with different FOV camera lens module options for image processing, laser detection and video camera applications.

-

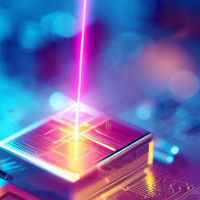

Thermal Camera Module, Thermal Imaging Module:

IADIY thermal camera modules adopts high-performance infrared detectors for ultra-clear thermal imaging and sccurate temperature measurement. As our manufacturing facilities provide optics and thermal camera modules design service and manufacturing of photoelectronic, optical lens, thermal infrared sensor module, and image processing.

-

Endoscope Camera Module, Videoscope Module:

As our manufacturing facilities provide optics and endoscope camera modules design service and manufacturing of electro-optical module, endoscope lens, image processing and lighting solution. It suitable for various industries, including industrial endoscopes, automobile endoscopes, and water, electricity and water pipe endoscopes.

-

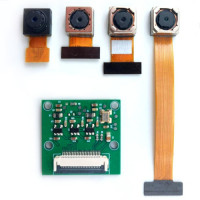

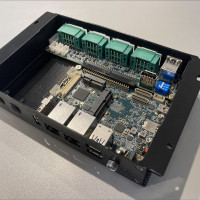

Custom Camera Module, Board Level Camera and Sensor Module:

Except the camera modules listed online, we also can custom make the camera module and sensor module as your requirements. You can visit

custom camera module

to review the introduction and customized requirements flow. Welcome your inquiry, please don't hesitate to

contact us.

Thermal Camera Module, Thermal Imaging Module: IADIY thermal camera modules adopts high-performance infrared detectors for ultra-clear thermal imaging and sccurate temperature measurement. As our manufacturing facilities provide optics and thermal camera modules design service and manufacturing of photoelectronic, optical lens, thermal infrared sensor module, and image processing.

Endoscope Camera Module, Videoscope Module: As our manufacturing facilities provide optics and endoscope camera modules design service and manufacturing of electro-optical module, endoscope lens, image processing and lighting solution. It suitable for various industries, including industrial endoscopes, automobile endoscopes, and water, electricity and water pipe endoscopes.

Custom Camera Module, Board Level Camera and Sensor Module: Except the camera modules listed online, we also can custom make the camera module and sensor module as your requirements. You can visit custom camera module to review the introduction and customized requirements flow. Welcome your inquiry, please don't hesitate to contact us.

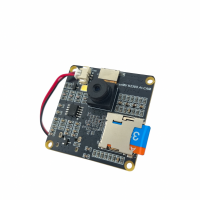

Thermal Camera Module

Thermal Camera Module, Thermal Camera Board, Thermal Imaging Module

Thermal Camera Module, Thermal Camera Board, Thermal Imaging Module

Thermal module is the core of a thermal camera, consisting of infrared detector and processing circuits. IADIY thermal camera modules adopts high-performance infrared detectors for ultra-clear thermal imaging and sccurate temperature measurement. As our manufacturing facilities provide optics and thermal camera modules design service and manufacturing of photoelectronic, optical lens, sensor module, and image processing. We dispose of an unsurpassed design and development capacity, comprising an in-house optics & photonics division, an hardware division and an software integration division making us the ideal choice for clients who wish to outsource crucial designs and manufacturing to a highly qualified and trusted partner.

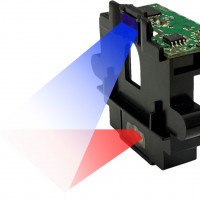

How does A Thermoelectric Module Work?

The higher an object's temperature, the more infrared radiation is emitted. Thermal camera can detect this radiation in a way similar to the way an ordinary camera detects visible light. It even works in total darkness because ambient light level does not matter. This makes it useful for rescue operations in smoke-filled buildings and underground. Thermal camera module is the core of the thermal camera, which detects infrared radiation and convert it into electric signals for thermal image processing. It can be applied in various fields such as outdoor night vision, temperature measurement, fire prevention, health and medical care, and autopilot. As the thermal camera module structure, we divide into 3 main sections:

1. Thermal Imaging Detector, Thermal Infrared Sensor

Thermal Infrared sensor is the key part of thermal camera module. There are two types of thermal modules. Uncooled LWIR thermal camera sensor module can provide crisp and clear thermal images under normal temperature conditions. Cooled MWIR Camera Module adopts a variety of image processing algorithms, which is suitable for extreme conditions and applications. It is designed can be easily integrated into infrared systems that require advanced cooling and high-resolution thermal imaging solutions. It can detect small targets at extreme ranges making them highly suited for long range applications in challenging weather conditions.

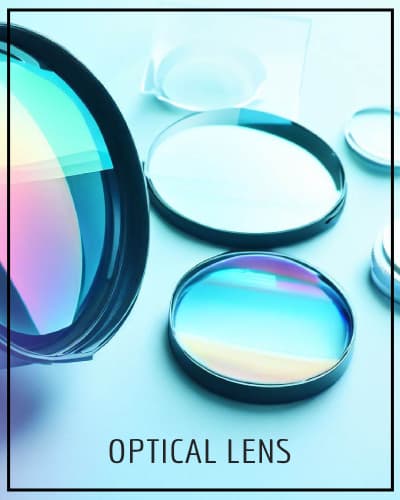

2. Thermal Imaging Lenses

Thermal imaging lenses, also known as thermal infrared lenses, are made from various IR-transparent materials, and our products use chalcogenide glass to achieve high infrared transmission. When choosing a thermal imaging lens, you can consider requirements like: spectral range, thermal sensitivity, resolution, range, and FOV(field of view), etc...

3. ISP+AI SOC Chip and Image Processing Circuit

The image processing chip and circuit is a necessary part for driving the thermal sensor. With the help of AI image enhancement technology, AI SOC embedded ISP and processor can support enhanced resolution and improved image quality, while improving object recognition response speed. Through the application of AI ISP, the video surveillance industry can achieve improvements in video image quality, optimization of intelligent analytics, and enhanced security protection.

More information please review camera module introduction or custom camera module requirements flow.

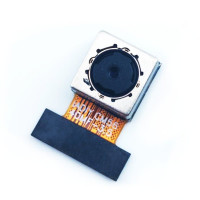

Endoscope Camera Module

Endoscope Camera Module, Endoscope Board Camera, Tube Camera, Videoscope Module

Endoscope Camera Module, Endoscope Board Camera, Tube Camera, Videoscope Module

As our manufacturing facilities provide optics and endoscope camera modules design service and manufacturing of endoscope lens, image processing module and lighting solution. We dispose of an unsurpassed design and development capacity, comprising an in-house optics & photoelectronics division, an hardware division and an software integration division making us the ideal choice for clients who wish to outsource crucial designs and manufacturing to a highly qualified and trusted partner.

As the endoscope camera module structure, we divide into four sections:

1. Tube Camera + LED Lighting

Image sensor is the key part of camera module. It decides the major parameters and features including image pixels and resolution, frame rate, dynamic range, sensitivity, and functions support, etc... With the requirements of camera lens: diameter size, FOV(field view angle), focal length, distortion, and the additional lighting resource or optical filter request.

2. Controller

External controllers are optional, depending on your actual application requirements. It provides convenient manual control operation like lighting ON/OFF switch, dimmer, snapshot/freeze frame, etc...

3. Cable (3A+3B)

The cable of endoscope camera can be custom made as your requirements like the length, diameter, detachable or not, and special environment reliability request, etc.

4. Connector / Signal Interface

The signal interface usually can support UVC or MIPI, also CVBS signal. And the connector can be modified as the customer's request, there is USB Type A, USB Type C, Mini USB Type B, Micro Type B, BNC female, RCA female, etc...

More information please review camera module introduction or custom camera module requirements flow.