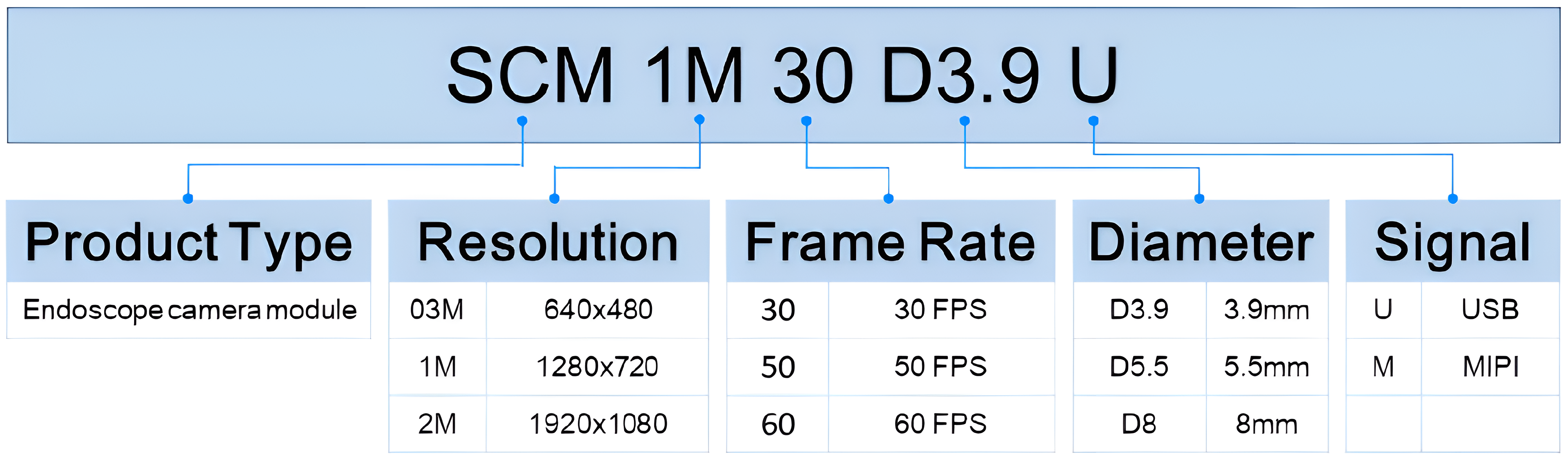

Endoscope Camera Module

Brand: IADIY

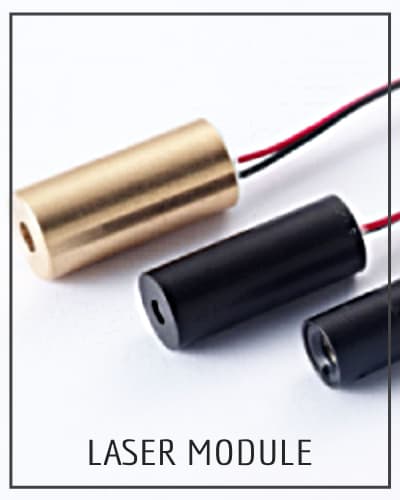

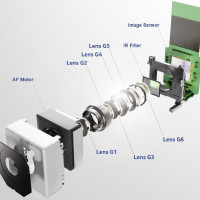

The SCM03M30D5.5U is a 0.3Mega Pixel, 640 x 480, VGA endoscope with small diameter. The lenses can be selected for different FOV applications. The USB cable length and LED light intensity adjuste..

$26.0

Brand: IADIY

The SCM1M30D5.5U is a 1mega pixel, 1280x720 high resolution endoscope. USB cable length and LED light intensity adjuster can be options. IP67 waterproofing, selectable FOV angle, compact size mak..

$38.0

Brand: IADIY

The SCM1M30D3.9U is a 1mega pixel, 1280x720 high resolution and very small diameter endoscope. USB cable length and LED light intensity adjuster can be options. IP67 waterproofing, selectabl..

$43.0

Brand: IADIY

The SCM2M30D8U is a 2mega pixel, 1920x1080 high resolution and very small diameter endoscope. USB cable length and LED light intensity adjuster can be options. IP67 waterproofing, selectable FOV ..

$48.0

Showing 1 to 4 of 4 (1 Pages)