Industrial Endoscope Inspection Cameras: A Guide to Borescopes

Posted By

18 Feb

0 Comment(s)

457 View(s)

- What is an Industrial Endoscope and How Does It Work?

- What are the Benefits of Using an Inspection Camera?

- How to Choose the Right Borescope for Your Needs?

- What Are the Best Applications for Endoscope Inspection?

- How to

Operate an Industrial Endoscope Inspection Camera?

What

is an Industrial Endoscope and How Does It Work?

-

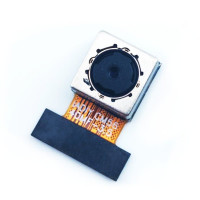

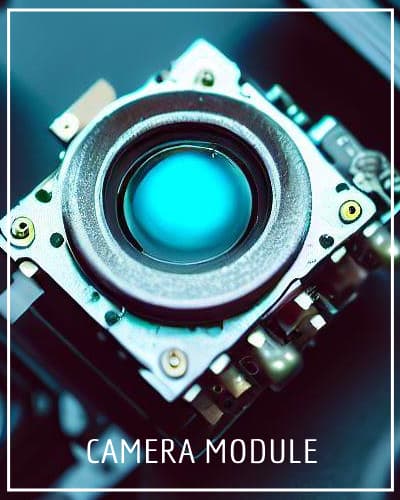

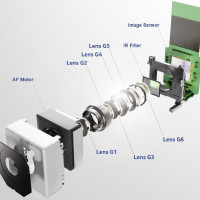

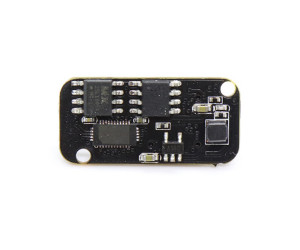

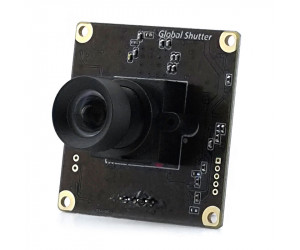

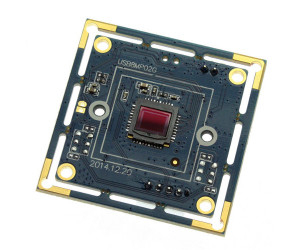

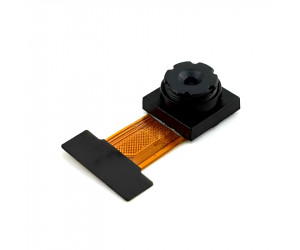

Understanding the Basics of an Endoscope

An industrial endoscope, or endoscope camera, is a specialized imaging device designed to inspect confined spaces and cavities that are otherwise inaccessible. It consists of a flexible or rigid probe equipped with a tiny camera, often coupled with an illumination source. The endoscope utilizes advanced optics to capture high-resolution images and transmit them to a display screen, allowing for real-time viewing and analysis. The fundamental principle behind the endoscope's operation is the use of light to illuminate dark areas, combined with a lens system that focuses the image onto a sensor, which can be digital or analog. This makes endoscopes invaluable for various applications, where traditional inspection methods may fall short.

-

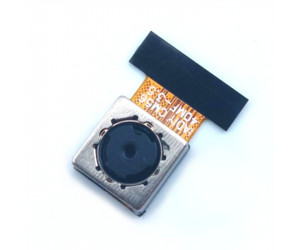

How Does an Endoscope Camera Perform Inspections?

An endoscope camera performs inspections by inserting its probe into the area of interest, such as pipes, engines, or mechanical assemblies. The camera captures images and video through its lens, which can be either a standard optical lens or a more advanced digital lens that provides enhanced image quality. Many modern industrial endoscopes also feature HD resolution, such as 1080p, which allows for clearer images with greater detail. The data collected can be recorded and stored using a memory card, or transmitted wirelessly to a computer or mobile device for further analysis. This capability significantly facilitates visual inspections by allowing operators to inspect components without disassembly, saving both time and labor costs.

-

Applications of Industrial Endoscopy

Industrial endoscopy has a wide range of applications across various sectors. In manufacturing, these inspection cameras are used to examine the integrity of machinery, detect defects in production lines, and ensure quality control. In the plumbing industry, endoscopes enable technicians to inspect pipes for blockages or corrosion without needing extensive excavation. HVAC systems also benefit from endoscope inspections, as technicians can assess ductwork and system components for cleanliness and optimal functioning. Additionally, automotive industries utilize endoscopes for engine inspections and diagnosing mechanical issues, ensuring that vehicles operate efficiently and safely.

What

are the Benefits of Using an Inspection Camera?

-

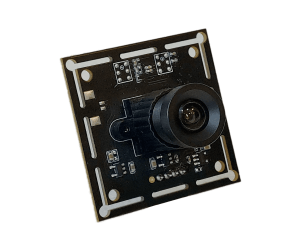

Advantages of HD Resolution in Industrial Inspections

The transition to HD resolution in inspection cameras has revolutionized how industries conduct visual inspections. With an HD endoscope, operators can achieve superior image quality, allowing for detailed examination of components. High-definition imaging helps in identifying even the smallest defects or anomalies, which can be crucial in preventing significant operational failures. The clarity offered by HD resolution can also facilitate better training opportunities, as technicians can learn to identify issues on high-quality images captured during inspections.

-

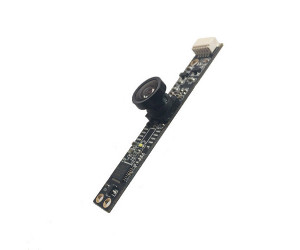

Why Choose a Flexible vs. Rigid Endoscope?

When selecting an inspection camera, one of the critical decisions is choosing between a flexible and a rigid endoscope. A flexible endoscope offers a significant advantage in terms of maneuverability, allowing it to navigate through complex pathways and around corners, making it ideal for plumbing inspections or any scenario where accessibility is limited. On the other hand, a rigid endoscope may be preferred for applications that require a stable view and where the inspection area is accessible. Rigid borescopes provide excellent image quality and can be more durable in environments where flexibility is not necessary.

-

Waterproof Features and Their Importance

Waterproof capabilities are another critical feature of many industrial endoscopes, particularly those used in plumbing or environments where moisture is a concern. An endoscope rated with an IP67 waterproof feature can withstand exposure to water and dust, ensuring its longevity and reliability. This durability is essential for maintaining the integrity of the device, especially when inspecting areas prone to liquid exposure. Waterproof endoscopes also lend themselves to various cleaning methods, thus maintaining hygiene and operational efficiency.

How

to Choose the Right Borescope for Your Needs?

-

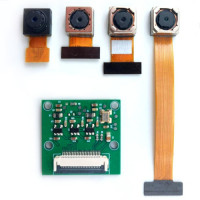

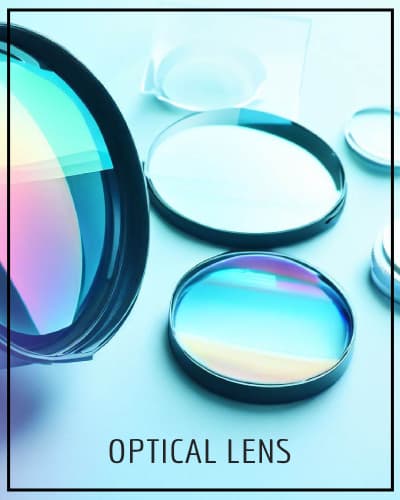

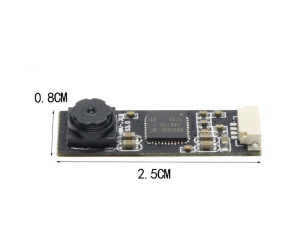

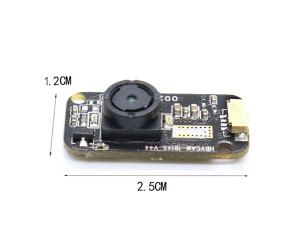

Key Specifications to Consider: Diameter, Length, and Lens Type

Choosing the right borescope involves evaluating several key specifications such as diameter, length, and lens type. The diameter of the probe affects the type of spaces the endoscope can access; smaller diameters are suitable for tight spots, while larger ones may provide better image quality. Additionally, the length of the endoscope needs to be considered based on the depth of the inspection area. Different lens types, including dual-lens or triple-lens configurations, provide varying perspectives and detail levels, which can be crucial depending on the application.

-

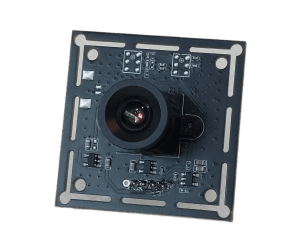

Understanding Digital vs. Analog Endoscope Cameras

When selecting an endoscope camera, it is essential to understand the difference between digital and analog options. Digital endoscope cameras typically offer superior image quality, enhanced features like Wi-Fi connectivity for easy sharing, and advanced image processing capabilities. They are compatible with various devices, including Android and iOS smartphones, which can enhance usability. Analog endoscopes, while still functional, may not provide the same level of detail or convenience as their digital counterparts, making digital options more favorable for modern inspection needs.

-

Evaluating Image Quality: Pixel and Resolution Factors

Image quality is a paramount consideration when selecting an inspection camera. Factors such as pixel count and resolution directly impact the clarity of the images captured. Higher pixel counts lead to sharper images, allowing for better detection of defects and detailed examination of components. A digital endoscope with a resolution of 1080p or higher is recommended for industries where precision is critical. Moreover, understanding how the camera's sensor interacts with its lens can further enhance image quality, ensuring that users can rely on their inspections.

What

Are the Best Applications for Endoscope Inspection?

-

Using Inspection Cameras in Plumbing and HVAC

Inspection cameras have become indispensable tools in plumbing and HVAC industries. Plumbers utilize endoscopes to inspect pipes for clogs, leaks, or structural issues without invasive methods. This capability allows for precise diagnostics, leading to quicker resolutions and reduced customer disruption. In HVAC systems, endoscopes help technicians assess ductwork for accumulation of debris or damage, ensuring efficient operation and air quality control. These applications highlight the necessity of endoscopes in maintaining systems that are critical for both safety and functionality.

-

Industrial Applications: Manufacturing and Maintenance

In the manufacturing sector, industrial borescopes play a vital role in quality assurance and maintenance. They enable operators to perform visual inspections of machinery and components, checking for wear, corrosion, or other defects that may impact performance. Regular inspections using endoscopes can lead to early detection of potential failures, ultimately saving costs on repairs and downtime. Moreover, in maintenance routines, endoscopes facilitate the assessment of hard-to-reach areas, ensuring that machinery operates at optimal efficiency.

-

Endoscope Inspection in Automotive Industries

While the terms thermal cameras and infrared cameras are often used interchangeably, there are distinct differences between the two. Thermal cameras specifically detect and visualize infrared radiation emitted by objects based on their thermal energy, producing thermal images that represent temperature variations. In contrast, infrared cameras can encompass a broader range of devices that capture infrared light, including those used for surveillance and night vision. Notably, thermal cameras focus exclusively on thermal radiation, whereas infrared cameras may also capture reflected infrared light. Understanding these differences can help users select the appropriate technology based on their specific application needs.

How to Operate an Industrial Endoscope Inspection Camera?

-

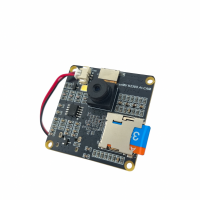

Setting Up Your Inspection Camera

Setting up an industrial endoscope inspection camera is a straightforward process but requires attention to detail for optimal operation. First, ensure that the camera's probe is clean and free from any obstructions that could impair visibility. Next, connect the device to a power source or charge it if it operates on a battery. Depending on the model, you may need to insert a memory card or connect to a computer via USB for image and video storage. Once set up, adjust the lighting settings on the camera to ensure that the inspection area is adequately illuminated for clear imaging.

-

Recording Images and Sharing Output with USB or Wireless Options

Most modern endoscope cameras allow for easy recording of images and video during inspections. Users can typically press a button to capture images, which are then saved to a memory card or internal storage. For sharing the output, many devices offer USB connectivity, enabling quick transfers to a computer for further analysis. Additionally, wireless options such as Wi-Fi connections allow for real-time streaming and sharing with mobile devices, providing flexibility in how inspection data is managed and utilized.

-

Troubleshooting Common Issues with Endoscope Cameras

While endoscope cameras are generally reliable, users may encounter common issues that require troubleshooting. If image quality appears poor, check the lens for debris or smudges that could affect visibility. Ensure that the lighting is adequate, as insufficient light can lead to unclear images. In cases where the camera fails to connect to a smartphone or computer, verify that the device's software is updated and that the correct settings are enabled. Proper maintenance and regular checks can help prevent many of these issues, ensuring that the endoscope remains a dependable tool for inspections.

-300x250h.jpg)

Leave a Comment